Spectra Energy compressor station offline while engineers investigate Searsmont gas release

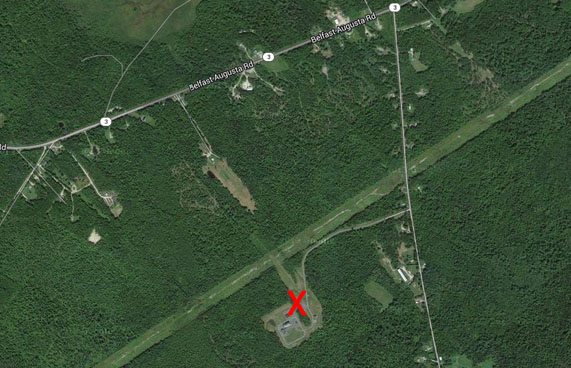

SEARSMONT — A team of engineers remains at a Spectra Energy pipeline compressor station in Searsmont attempting to determine why a pressure valve blew Dec. 31, sending a tower of gas 100 feet into the cold night air. Meanwhile, the station has been shut down, while gas continues to run through the pipeline to other compressor stations in Maine.

“Engineers are on the ground reviewing it,” said Spectra spokeswoman Susan Waller, from the company’s Houston corporate office, almost a week after the incident shook residents awake within a 10-mile radius just before midnight New Year’s Eve.

Community meeting, Jan. 21

The public is invited to an informational meeting Jan. 21 at the Searsmont town office, 6 p.m.

The meeting is being held at the suggestion of the Searsmont Fire Department, so that citizens could air questions and concerns. Maritimes and Northeast agreed, and will be sending several representatives: Don Thompson, area manager for the Richmond compressor station; Cara Bailey, senior right-of-way specialist (her role is to communicate with landowners); and Marylee Henley, director of stakeholder outreach.

The goal is “to educate people on how a compressor station works and what to expect from it,” said Henley.

”I want to have an informal meeting so people can be informed,” said Searsmont Fire Chief James Ames.

That night, an emergency shutdown valve blew between 11:50 and 11:55 p.m., opening a 50-minute window when approximately 70,098 cubic feet of natural gas released into the air. The pipeline control valves were closed remotely by engineers in Houston, Texas, at 11:58 p.m., and the compressor station was shut down at 12:37 p.m., said Waller.

“The system is designed with fail-safe valves that allow the station to vent natural gas from the station in case of emergency,” said Waller. “In this particular instance the system operated as designed and vented the station. There are valves along the pipeline spaced according to the U.S. Department of Transportation, Pipeline and Hazardous Materials Safety Administration regulations. Maritimes and Northeast has voluntarily installed valves that can be closed remotely.”

On Jan. 6, she said the team of two to four engineers remained in Searsmont after arriving there Jan. 2.

“The engineers are still investigating what happened,” she said.

Some residents continue to be concerned about the safety of the gas pipeline and the compressor station. Susan Totman, who lives 1,200 feet from the facility on the New England Road, worries that it will blow, like others she has seen recorded on YouTube.

While the Searsmont station is shut down, the pipeline system does not currently need it to operate, “because there is so much demand for natural gas,” Waller said. “Natural gas is always in demand during the winter.” Consequently, the pressure remains high enough in the pipeline to move the gas.

The venting of that gas just minutes before the arrival of the new year, however, alarmed residents throughout the area, as news of the noise, described as a jet taking off in flight, traveled quickly through Facebook.

Read: Natural gas line in Searsmont blows pressure valve, alarms area residents with noise

The Searsmont Fire Department responded, but its role was standby; if an explosion occurred, firefighters would be evacuating people from their homes, said Assistant Fire Chief Wayne Woodbury. The station’s controls were handled that night from the Houston crew, said Spectra.

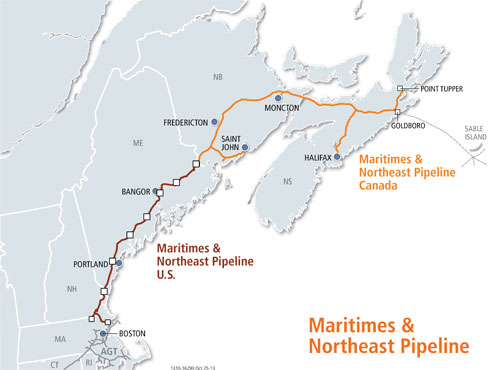

The gas that runs through rural Maine in a pipeline measuring approximately 30 inches in diameter originates off of Nova Scotia’s shore near Sable Island.It is pumped from beneath the Atlantic and then routed via pipeline to customers in the Maritimes, New Hampshire, Boston and parts of Maine. There are lateral stations in Veazie, Bucksport and Westbrook.

The pipeline is part of the Maritimes and Northeast Pipeline, and is a subsidiary of Spectra Energy, which owns 77 percent of the venture. Exxon Mobil and Emera Inc., own the remaining shares. The pipeline was constructed in 2008-2009, and doubled the capacity of the Maritimes system. It is designed to transport approximately 785 million cubic feet of gas a day and the actual volumes transported fluctuate on a daily basis, said Waller.

The pipeline

Maritimes and Northeast Pipeline (Maritimes) is a 684-mile transmission pipeline system built to transport natural gas from developments offshore Nova Scotia to markets in Atlantic Canada and the northeastern United States.

A joint venture of Spectra Energy Partners (77.53 percent), Emera Inc. (12.92 percent), and ExxonMobil (9.55 percent), Maritimes is headquartered in Halifax, Nova Scotia and operates an additional business office in Waltham, Massachusetts.

The Maritimes system consists of an approximately 30"/24" diameter underground mainline running from Goldboro, Nova Scotia through Nova Scotia and New Brunswick to the Canadian border at Baileyville.

The pipeline continues through Maine and New Hampshire into Massachusetts where it connects with the existing North American pipeline grid at Dracut, Massachusetts. The pipeline also extends from Methuen to Beverly, Massachusetts.

A compressor station, such as that in Searsmont, is to boost pressure and increase the gas flow. According to Waller: “Compressor stations are designed to vent gas safely during an emergency. Maritimes and Northeast is responsible for securing the facilities and consulting with public safety agencies as necessary.”

“Natural gas is pressurized as it travels through the interstate pipeline system,” said Waller. “To ensure that the gas continues to flow optimally, it must be periodically compressed and pushed through pipelines. Over distance, friction and geographic elevation differences slow the gas and reduce the pressure, so compressor stations are placed typically 40 to 70 miles apart along the pipeline to give the gas a ‘boost.’ These stations operate day and night, year-round to push re-pressurized gas through the pipelines.”

Other Maine compressor stations are in Richmond, Eliot and Westbrook.

The venting of gas New Year’s Eve is not the first incident at the Searsmont plant. In March 2010, a loud hissing noise woke residents in the area around the plant, according to the Bangor Daily News. Residents also reported physical effects — headaches and nausea — from the released gas. A community meeting was held following that incident, the newspaper reported, and the cause was attributed to a malfunctioning rubber gasket associated with a relief valve.

The 2014 New Year’s event sparked a shock wave as residents voiced public safety and environmental concerns, especially about the threat of gas explosions. They have asked why the Searsmont plant was immediately shut down when a local engineer arrived there New Year’s Eve. Was the plant truly being controlled by a Texas crew, they want to know.

While some said nearby residents went to the hospital following the Jan. 1 gas venting, both Waller and Searsmont Chief Ames said they had not heard that.

“We are not aware of anyone being transported to the hospital,” said Waller.

Andrew Butler, who lives in Searsmont, reported that he did go to the hospital five hours later because he felt nauseated, but he did not connect his symptoms with the compressor station gas venting. He said he smelled nothing inside his house.

Waller said natural gas is injected with an oderant, which produces the rotten egg odor that is generally associated with natural gas and liquid propane.

“The natural gas released during an emergency shutdown is not dangerous,” she said. “While release amounts vary from station to station, they fall within strict guidelines mandated by federal regulations.”

She said the company called residents the next day.

“The intent was to reach out to the nearby neighbors to answer any questions they may have had regarding the emergency gas release that occurred,” she said.

Waller said compressor stations are equipped with emergency shutdown systems “that safely halts operation when the slightest irregularity is detected.”

She said the system halts the compressor units, isolates the station piping and releases the gas within the station: “into the atmosphere in a safe and controlled manner. In addition, all emergency shutdown systems are fully tested annually per Department of Transportation regulations.”

“Interstate natural gas pipelines and facilities such as compressor stations are highly regulated facilities that must meet rigorous safety standards established by the Federal Energy Regulatory Commission and the U.S. DOT Pipeline and Hazardous Materials Safety Administration. Spectra Energy’s compressor stations integrate a variety of safety systems and practices designed to protect the public, our employees and our property,” she said.

The Pipeline and Hazardous Materials Safety Administration (PHMSA) collects all violations and consent agreements concerning the transfer of gas and hazardous materials in pipelines across the country. PHMSA describes itself as the, “federal safety authority for ensuring the safe, reliable, and environmentally sound operations of our nation's pipeline transportation system. An important component of OPS's mission is to promote pipeline safety communication and education.”

Available cases at its website go back more than a decade. According to data collected there, three pipelines owned by Spectra have been cited for various deficiencies.

In 2007 and 2010, the Algonquin Gas Transmission pipeline was cited in a warning letter about corrosion material and maintenance. In 2013, the Texas Eastern Transmission pipeline was fined $87,100 for corrosion control, maintenance and manuals for gas pipelines.

The safety of gas pipelines for nearby residents becomes more of a public concern as the network only grows throughout the country, and in Maine. Agreements were signed last year to run a natural gas pipeline from Augusta to Rockland and the city is preparing for that.

The relationship between the local fire department and the Waldo County Emergency Management Agency includes meetings, said Waller.

“We meet and host meetings with local fire departments along the pipeline route on a rotating basis,” said Waller. “We often invite county and state representatives to the same meetings.”

Dale Rowley, Waldo County EMA director, said Jan. 7 the function of firefighters and emergency response in the event of a natural gas fire is limited without proper equipment, special suits and an adequate supply of alcohol resistant foam.

If a fire or an explosion occurred, procedures would call for shutting off the flow of fuel, evacuating residents within a 1,000- to 2,000-foot radius, and letting the fire burn itself out.

He said Searsport, where ships and trucks transport a variety of caustic and hazardous materials, keeps two response trailers with foam on hand in the event of a hazardous materials release.

Despite its high flammability, natural gas is not considered an extremely hazardous material, as opposed to caustic soda or ammonia.

To neighbor Susan Totman, the bottom line is safety, no matter how the product is classified. Her home lies 1,200 feet from the compressor plant.

Six days after the incident at the compressor station, she said: “I am still afraid as I was that night. I don’t want to live there. I don’t want my family living there.”

She said she has watched clips on YouTube of other compressor stations blowing up. The noises recorded there sound exactly like what she heard New Year’s Eve, she said.

“I’m afraid it’s going to blow up,” she said.

She has read the safety precautions advised by Spectra and cited incongruities.

“They are a corporation,” she said. “They talk out of both sides of their mouth. Corporations don’t care about the little guy.”

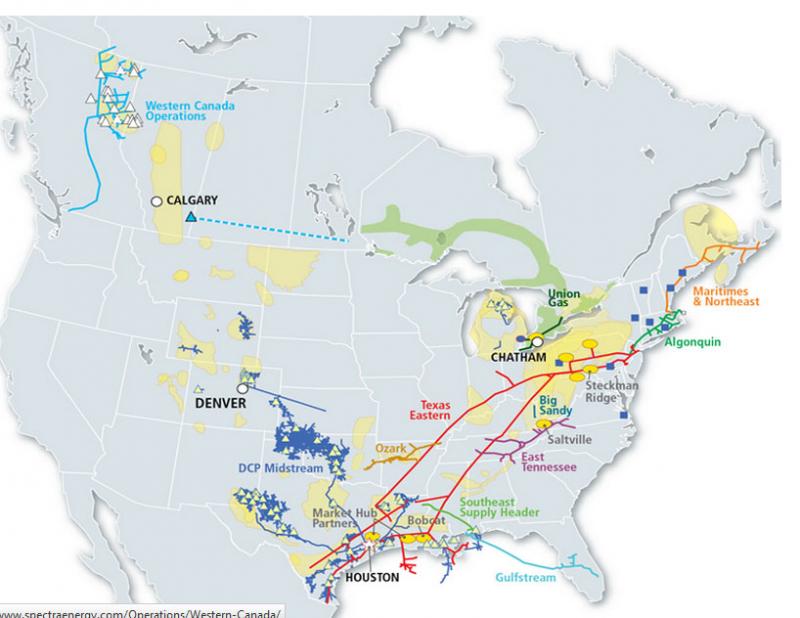

Spectra incorporated in 2006. It is traded on the New York Stock Exchange (SE). Spectra owns and operates natural gas gathering and processing facilities, and is a natural gas infrastructure company.![]() The company also has a 50 percent ownership in DCP Midstream, the largest producer of natural gas liquids and the largest natural gas processor in the United States.

The company also has a 50 percent ownership in DCP Midstream, the largest producer of natural gas liquids and the largest natural gas processor in the United States.

In November, Spectra reported third quarter 2013 cash available for distribution of $66.3 million, compared with $56.3 million in the prior-year quarter. Reported net income from controlling interests was $59.6 million for the third quarter 2013, compared with $46.1 million in the third quarter 2012. Excluding a special item of $5.8 million in transaction costs, ongoing net income from controlling interests was $65.4 million for the third quarter 2013, compared with $46.1 million in the prior-year quarter.

Signs of a Natural Gas Pipeline Leak, courtesy of Spectra Energy

Any one of the following could be a sign of a leak:

• Blowing or hissing sound

• Gaseous or “rotten egg” odor

• Flames, if a leak has ignited

• Dead or discolored vegetation in an otherwise green area

• Dust blowing from a hole in the ground

• Continuous bubbling in wet or flooded areas

Hazards Associated with a Natural Gas

Pipeline Leak or Rupture

• Dizziness or suffocation if leak occurs in a confined space

• Ignition/fire if ignition source is present during leak which may result in burns

• Potential explosion if the natural gas is mixed with air

• Projectiles ejected from the force of escaping gas

What to Do If You Suspect a Pipeline Leak

Your personal safety should be your first concern:

• Evacuate the area and try to prevent anyone from entering.

• Abandon any equipment being used in or near the area.

• Avoid any open flames.

• Avoid introducing any sources of ignition to the area (such as cell phones, pagers

and two-way radios).

• Do not start or turn off motor vehicles or electrical equipment.

• If you suspect natural gas has leaked into your house, evacuate immediately. Do

not turn lights on or off, use the phone from the house or do anything that could

produce a spark.

• Call 911 from a safe location or contact your local fire department or law

enforcement personnel.

• Notify Spectra Energy by calling the toll-free emergency number (below) or the

emergency number listed on the pipeline marker.

• Do not attempt to extinguish a natural gas fire.

• Do not attempt to operate any pipeline valves.

In case of an emergency, call toll-free 24 hours a day.

1-800-231-7794

Editorial Director Lynda Clancy can be reached at lyndaclancy@penbaypilot.com; 706-6657.

Event Date

Address

United States