Making hard cider from scratch

There are two things I’m sure of. I know the zombie apocalypse is coming and I know that if and when the power shuts down, the roads are barricaded and the Maine militia is cutting through the forest, my skills as a writer aren’t going to mean squat in a bartering economy. What am I going to do, proofread The End is Nigh signs?

So, I decided last fall to take up hard cider-making. That, I know, is a valuable skill. Our Applejack-making, moonshine-crafting forebears never had a problem bartering for that.

I didn’t know what kind of journey I was in for, but I took a bushel of apples up to Central Street Farmhouse in Bangor for the annual apple pressing in October to see if I could get some happy juice out of it.

Not only did I learn to hand-crank the press, watching the apples mash to pulp in the grinder, but it was gratifying to see all of the cider come from it. It smelled delicious, all golden brown and frothy once the jug filled. Central Street Farmhouse had a one gallon brewing kit (easier to store and less risk in making mistakes), so I went for it. This was my journey from the first apple to the first sip.

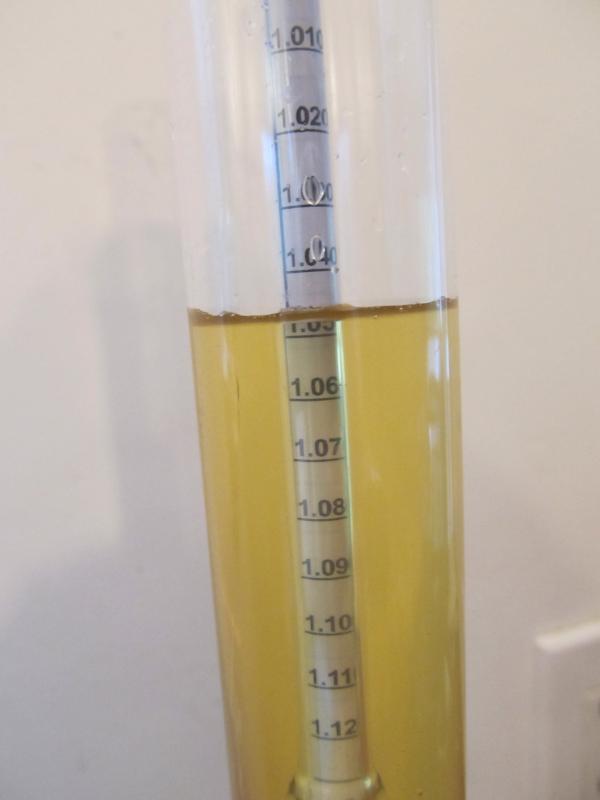

Sanitizing the bucket and all of the equipment required precise care. As someone who failed chemistry in high school, I looked at the hydrometer I’d bought with about as much enthusiasm as you would have while picking up dog poop on the lawn without a baggie. But I filled the beaker with pale cider and took the reading, measuring its original gravity.

“That is one mother of a urine sample,” my friend said.

After some trial and error (I didn't know you needed to put water in the airlock-my first mistake), I got 'er going and within 24 hours had the first batch fermenting with the tell tale sound of “bloop.” That was the yeast eating away at all of the sugars and releasing the gas through the airlock.

I waited about three weeks before racking the gallon batch with a plastic siphon into the secondary fermenter (a carboy) and popped on another airlock. With all the dead yeast cells siphoned out, the cider took on a hazy, honeyish color. Just beautiful to look at. One thing I did not know is that the sanitizer stains dark counter top. Big expensive mistake. I’m still living with the round white circle of the bucket bottom on my dark counter top. Want. To. Kick. Myself.

After the rest of the sludge at the bottom settled, a week later, I took another hydrometer reading. This time the ABV came out to be about 6.8 percent alcohol. I used the siphon to rack the cider into sanitized bottles (Coronas worked best) and popped a carbonation tab into each one before clamping an orange bottle cap onto it with my bottler. Time once again to let it settle.

Another week later, my husband and I were eager to try it. We poured the first bottle into a pint glass. I let him try it first.

"It's cider vinegar," he said.

I tried it: "No, it's not."

He backtracked.

"OK, it's just very dry."

Even with a carb drop in it, the final batch came out still, not fizzy like I expected. The cider was as pure as the day the apples were pressed, but the initial taste was super dry and tart, almost sour. I could go on about how I made four more batches of cider into the winter. Some bottles came out effervescent, while others remained still. I’m no expert at it, but it has taught me two more things: My writing and my cider-making aren’t going to get me very far in a barter economy. And, if squirrels can get drunk on fermented apples lying on the ground, at least I can give it to the squirrels.

Note: This article originally appeared in The WAVE Magazine (Fall/Winter 2017-2018) with errors. Here is the corrected version.

Kay Stephens can be reached at news@penbaypilot.com

Event Date

Address

United States